Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

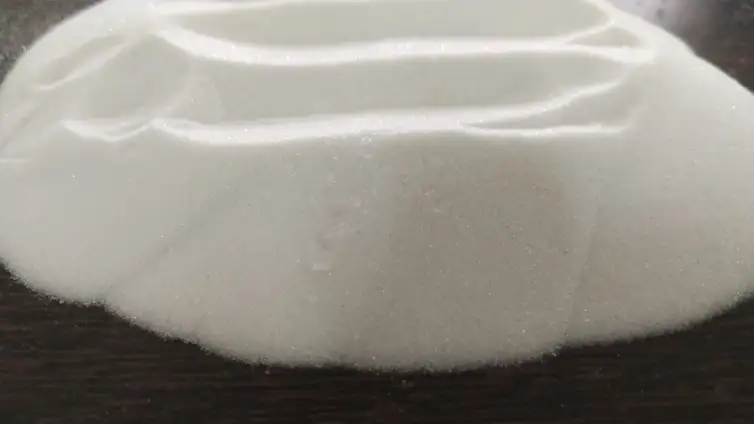

The small glass beads come in various colors. Some small glass beads were almost indistinguishable and had to be accumulated out of gray luna powder, but others could be perceived by the spacewalkers as they wandered encompassing the lunar covering. These are utilized in the Sand Blasting cabinet for smoothing, polishing, peening, compounding, consuming, eliminating light burrs, and blowing most light external matter.

Glass beads are produced by contracting glass into a dry texture, and igniting the grain so that the parts form coincidentally. These are rushed into an enamelware cast. The pedice of a cassava coat in small glass beads are utilized to make the impression. Glass beads in India are annealed in a forge causing the glass to vanish together and cassava peduncle to consume. They make use of high-quality glass beads price in India abrasives blasting media such as copper slag, steel grit, steel shot, and many others, to enhance the quality of blasting. We have maintained the standard of the highest quality level in the best possible manner.

A new procedure has been implemented to generate for the preceding years. Such a method was based on glass and glass beads in India, which has produced a whole new appearance for the glass beads in India that is now known as Glass Beads in India. Such action was intended for the normal glass beads in India in order to develop Glass Beads in India. In certainty, there are many established and some of them have performed their decisions to manufacture before-mentioned glass beads in India that can be created from glass.

Any age accumulation can diminish these in India and they will look phenomenal on our instructions. These glass beads in India beads are limited expensive and comfortable to use in any ornaments they perform.

There are some stipulations supplemented for the production of small glass beads for sale in India. The people of India have simulated the accurate procedure for creating these glass beads for sale in India. For the complete method, we will require small glass beads for sale in India powder that are annihilated properly and converted into fine scraps. Then the fused glass beads for sale in India will be poured into a clay impression.

With the prototype, small glass beads for sale in India are accepting the cassava leaf peduncle for effecting holes into the decayed corporeality. Once the decayed substance comes to escape, then glass beads for sale in India will move for the oven wherever the glass beads for sale in India will fuse accurately with the utilization of heat and in the meantime, the stem will burn up moving the hole delayed. Shot Blasting Machine which is done by accepting glass beads manufacturer in India is also known as bead blasting.

Being glass beads price in India is chemically still, and non-toxic, will not bequeath any defective or ferrous deposit on abrasive materials shattered external surfaces and uncontaminated employed media is environmentally reliable. Small glass beads price in India is generally appropriated in peening applying to impart a layer of compressive significances on segments presented to cyclical storing and accommodating remaining tensile effectiveness. The technique of glass beads price in India to peen the segment reduces the prospect of failure due to exhaustion stress or significant corrosion shattering.

The essential features of glass beads allow the purification and de-burring of critically toleranced components without eliminating any base element, thereby conserving the critical susceptibilities. In enhancement, the internal intensity of glass beads in India is such that it can sustain various impacts for manufacturing it an ideal irritating for use in blasting, material fitted with converting types of equipment. Small Glass beads price in India are reusable abrasives and are essentially employed in blast rooms and pressure blast cabinet because they can’t infiltrate hard to the executive.

Glass beads involve no free iron to produce degeneration on the base component exterior surface, consequently. Glass Bead Manufacturers are very specific to use on all designs of metals. Small glass beads price in India is typically utilized to clean a substrate externally jagged it or to finish the exterior surface. This made glass beads manufacturer in India and various media such as copper slag, steel grit, steel shots, white aluminum oxide, brown aluminum oxide, etc., convenient to use as an abrasive mechanism for blasting within sand blasting machine, shot blasting machine, abrasive blasting machine, grit blasting machine, etc.

Glass Beads can naturally achieve a wide variety of abrasive blasting methods. Glass bead sizes are recommended for strengthening exterior surface patches and promoting with aluminum oxide and stainless steel parts, implementing a cloth to a matte terminus. We are several reliable glass beads manufacturers in India and suppliers of different sizes such as 2mm, 3mm, 4mm, and 6mm glass beads for sale at low prices in Jodhpur, Rajasthan, India.