Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

Glass Bead Size A are spheres of solid glass. They are made from colorless glass for a variety of industries and are frequently used for blasting, filler, and traffic safety due to their high strength, chemical stability, restricted thermal expansion, and superior flowability.

We are the best manufacturers of various types of glass beads and blasting devices. To give the workpiece a gleaming finish, we provide the best quality beads and tools at the most reasonable price.

We are the best wholesalers and manufacturers of all types of glass beads and shot blasting machine in India, including Jodhpur, Jaipur, Ahmedabad, Pune, Delhi, Faridabad, Gurgaon, and Kolhapur. We also provide glass beads and blasting machines on an urgent basis, according to customer's requirements.

| Grade | A |

| US Sieve | 20-30 |

| Inches Max | 0.0331 |

| Inches Min | 0.0234 |

| Microns Max | 850 |

| Microns Min | 600 |

| Min % Round | 65 |

The methods of thermal and optical properties analysis and durability testing of glass bead materials are summarised and elaborated in this study for possible use of glass bead price materials to exterior wall surfaces of structures.

Furthermore, when these glass bead suppliers in India materials are applied to building facades, when the angle of sunlight reflected on the facade surface is high, the facade surface produces a big specular reflection on the road, which may have negative pedestrian consequences.

As a result, it is necessary to research and execute theoretical and technical elements of reducing specular reflection from glass bead materials. This study will also present a possible possibility of reducing specular reflection through proper glass bead design.

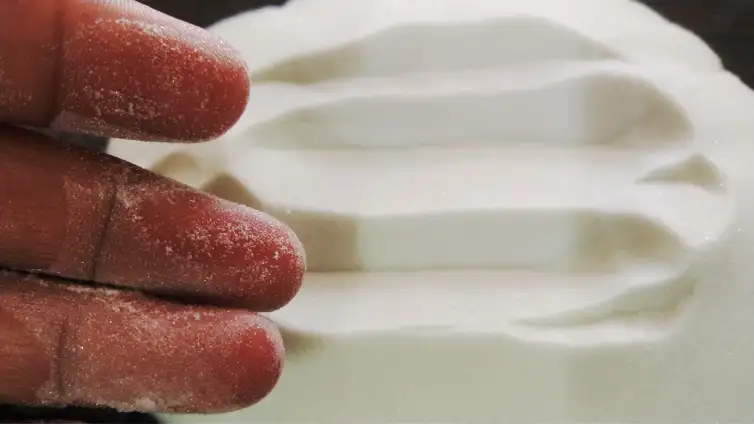

Most of the new glass bead size A had a rough surface that needed to be smoothed and cleaned. The following steps were taken to smooth the beads: Metal wire was used to thread the beads together after they were set on a flat surface of a stone.

To polish the beads, they were carefully rubbed on the stone. A stick was inserted or fixed through them and pressed against the spinning stone of a grinding machine to smooth them out even further. Injury was avoided at all costs.

Another option for smoothing was fine sandpaper. The glass bead give different size Awere strung together with a needle and thread to make necklaces,