Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

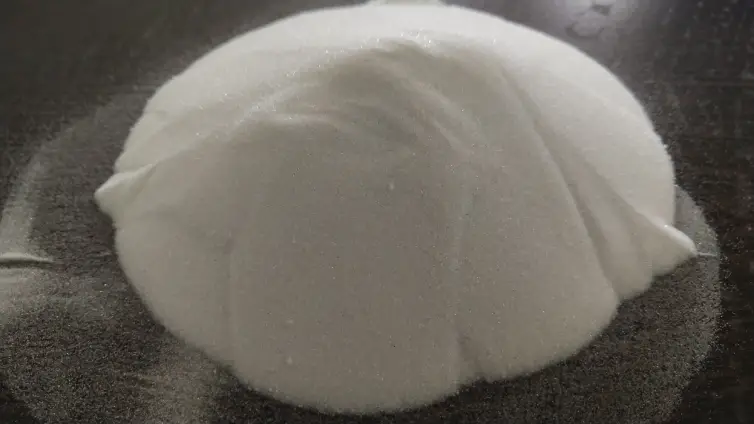

Glass Bead Size AB is a spherical abrasive made of lead-free soda-lime glass with no free silica that is chemically inert. Glass Beads can be used on any metal, regardless of hardness, and leave no impurities or residues on the surface. They can also be used to smooth out surface imperfections, increase corrosion resistance, and reduce fatigue by stress relieving machined and forged parts. Glass beads for cleaning, brighter satin finishes that are smoother than angular glass beads abrasives, with no dimensional change to items.

In Rajasthan and across India, including Jodhpur, Jaipur, Ahmedabad, Pune, Gurgaon, Delhi, and Faridabad, Airo Shot Blast is the premier manufacturer and supplier of glass beads of all types and sizes. We make a variety of glass beads, including shot peening beads, glass bead blasting, and road marking beads, in a variety of sizes, including large glass beads, small glass beads, micro glass beads, 2mm, 3mm, 4mm, 6mm glass beads, and more.

1.) Surface Treatment:

Cleaning and surface finishing using glass beads cost include polishing, deburring, sanitising, descaling, coating removal, and surface blending. They can also be used to sanitise metal parts like medical implants and devices, as well as stainless steel fabrications utilised in the food and pharmaceutical industries.

2.) Shot Peening:

Glass beads are used to induce compressive stresses in metal aviation engine blades, turbine rotors and components, gears, shafts, and other similar products, which improves their performance and service life..

3.) Road Marking:

Reflective lane markings made of glass beads improve visibility and safety on the road.

The glass bead used in shot blasting is an abrasive that permits the following procedures to be carried out:

Unlike other abrasives, the glass bead size AB does not remove the metal base, does not contaminate the surface treated, and does not leave incrustations, resulting in a good superficial finish.

Cleaning and removal:

The cleaning process is carried out by a forceful pressure on the surface, which removes all impurities without harming the metal basis. It does not rip off the covering and metal base as if it were a cutting tool because it is spherical and lacks edges and rims. As a result, shot blasting with glass bead size AB is still permitted in circumstances where tight dimensional tolerances are required.

Decorative finishing:

The dull finish created by shot blasting with glass beads manufacturers on steel, aluminium, stainless steel, brass, tin, acrylic, plastic, and other materials is very unique, adding value to the work..

Two advantages are added in this item:

In general, large-diameter glass bead size AB are used to provide a finish with deep grain and a dull surface; on the other hand, smaller-diameter glass beads produce a finer and duller finish.

Engravings:

The difference between the zones that have not been treated (shiny) and the zones that have been shot blasted produces the engraving that is done by shotblasting (dull).

Because of the low abrasiveness of glass beads, these engravings are usually done with masks manufactured specifically for this purpose. Although other abrasives can be used, glass beads ensure a superb finish and a significantly longer lifetime for the masks employed.

Shot peening:

It's the result of a fast-moving stream of spherical particles compacting a metallic surface. Because of the plastic deformation caused by the hammering motion (peening), the surface is crushed, resulting in compression stresses parallel to the surface ranging from 5 to 10 mils (thousandths of inch) in depth. This effect is used in parts such as gears, axles, springs, rods, and other components that are subjected to flexion forces that create traction stresses on the surface.