Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

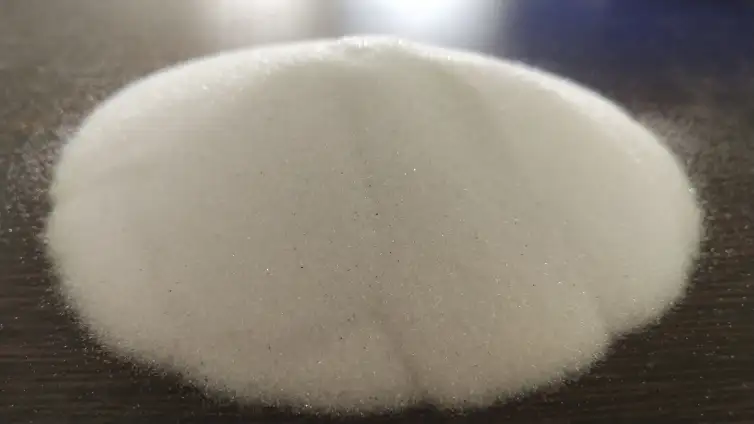

Glass Bead GB 270 FINER differs from other types of media in that they are constructed of soda lime-type glass rather than metal or plastic. Because this is a strong substance, it can withstand blasting without breaking. However, the greatest advantage of glass beads is that they are devoid of lead and silica.

This means that glass beads, when used as a blasting media, do not leave any impurities behind that could harm or corrupt the completed parts, making them one of the safest blasting media options. This is useful in the medical field and other fields where cleanliness is critical.

Glass Bead GB 270 FINER with a diameter of 0.05-0.00mm are mostly used for cleaning and polishing surfaces. In Rajasthan and throughout India, we are the leading manufacturers and suppliers of all types of glass beads and blasting machines.

We manufacture portable sand blasting machine, pressure blasting machines, wet blasting machines, suction blasting machines, automatic sand blasting machines, blasting equipment, nozzles, and more. Because we are the producers, you will get the best price from us.

When compared to other blast media, glass beads suppliers might be safe. Glass bead blast media, in example, can be a good alternative to silica sand depending on your application. While silica sand is still legal, it is becoming more regulated as a source of a range of health issues, including silicosis.

This comprehensive guide about silica sand and sandblasting may be found here. Glass Bead GB 270FINER blasting also has the advantage of being able to use them for several cycles before they stop cleaning a surface. Glass bead manufacturer media typically lasts 4–6 cycles before needing to be changed.

Finally, glass beads can be employed in either a suction or pressure blast cabinet in India. This makes it adaptable, and it can help you save money on your blast cabinet by providing a blast cleaning media (suction feed cabinets are more affordable than pressure feed).

It doesn't clean as quickly as other media and doesn't last as long as harder blast media like steel. Glass does not clear as quickly as steel grit, steel shots, or even copper slag because it is not as hard as these blast media.

Furthermore, Glass Bead GB 270FINER does not leave a profile, which can be an issue if you require a profile for your paint to stick to. Finally, glass bead GB 270FINER blasting is superior to steel grit, shot, and aluminium oxide.

In general, the higher the pressure, the bigger the impact and the faster you can blast. However, it may cause alterations to the surface of your glass bead GB 270FINER product. Pressure blasting is faster than suction blasting, but it can also cause surface alterations (if blast time or pressure is not well controlled).

It's always a good idea to start with a low blast pressure and gradually increase it until you find the one that's right for you. Glass bead blasting requires a maximum blast pressure of 80 psi for suction blast cabinets and up to 40 psi for pressure blasting.

Using these values as a guide, you should be able to gradually establish the proper blast pressure and duration.