Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

Blasting using glass bead GB 170/325 allows you to remove a variety of surface flaws, such as burrs, rust, and paint, leaving behind a beautifully polished matte finish. Finishing systems have a large variety of several types of abrasive glass bead blasting media for your blasting needs. Despite the fact that glass is made of silica, glass bead GB 170/325 contain no free silica, posing no health risk.

Clean efficiently at 45 to 60 degree nozzle angles by recycling numerous times. Coarse beads peen to more intense levels and peen deeper zones in the surface, removing bigger, tougher soils. Fine glass bead GB 170/325 remove smaller, lighter soil, have a higher impact per kilogramme, clean faster, peen at lower intensities, and peen the outer zones of surfaces.

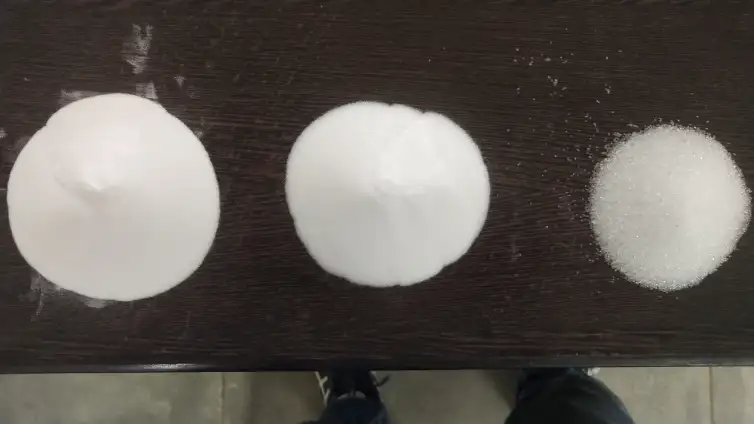

Glass Bead comes in different shape and sizes namely glass bead size 2mm, 3mm, 4mm, 6mm, large, small, big, micro and it is mainly used in blasting machine for shot blasting, shot peening, road marking and has many other applications, We manufacture and supply all type of glass bead and blasting machines in all over India like Jodhpur, Jaipur, Ahmedabad, Pune, Delhi, Gurgaon, Indore, Faridabad, etc.

| Grade | A |

| Designation | AH |

| U.S Mesh Size | 170-325 |

| Maximum Nominal Diameter | 0.0035 in 90 microns |

| Minimum Nominal Diameter | 0.0017 in 45 microns |

| Minimum Round Percentage | 85% |

Glass Beads: Although glass is not as harsh as many other industrial abrasives, it is widely employed in a variety of sectors. Glass bead GB 170/325 is a great option for projects that need a softer, brighter finish. It's ideal for tasks involving stainless steel, aluminium, and other metal substrates that require a milder abrasive. If the pressure is kept below 80 PSI, glass beads can be reused for an average of 8-10 passes through the nozzle.

Crushed Glass: Typically, crushed glass bead suppliers made from recycled plate or bottled glass. Before being sieved for size, it goes through a crushing rod mill. Sand, garnet, and aluminium oxide can all be replaced by crushed glass. The initial cost is reasonable, and the recyclability is excellent, with an average of 8-12 passes.

Aluminium Oxide: The enhanced hardness and strength of aluminium oxide are its distinguishing features. It is used in a variety of applications, including anti-slip surfaces, industrial blasting media, and as a raw ingredient in refractories. It's made for abrasive pressure blasting and suction blasting of practically any surface, including glass, granite, marble, steel, and cast iron. It is frequently used in the preparation of surfaces prior to painting or coatings because of its capacity to thoroughly etch.

Silicon Carbide: Silicon carbide is the hardest abrasive blasting substance available, making it ideal for the most difficult surface finishing jobs. It comes in a variety of colours and purities. It has a wide range of applications, including bonded abrasive tools, lapping, polishing, glass etching, and heavy-duty blast cutting. This abrasive is frequently used in applications where subsequent processes will need brazing.

Plastics: Crushed urea, polyester, or acrylic are used to make plastic abrasive, which is a dry thermoset cleaning media. Each type of media comes in a variety of hardness and particle sizes. Plastic is often recognised as the best medium for cleaning moulds, blasting plastic parts, and other applications where the substrate material cannot be removed. Automotive, aviation, yachting, electronics, and industrial applications are all common industries.