Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

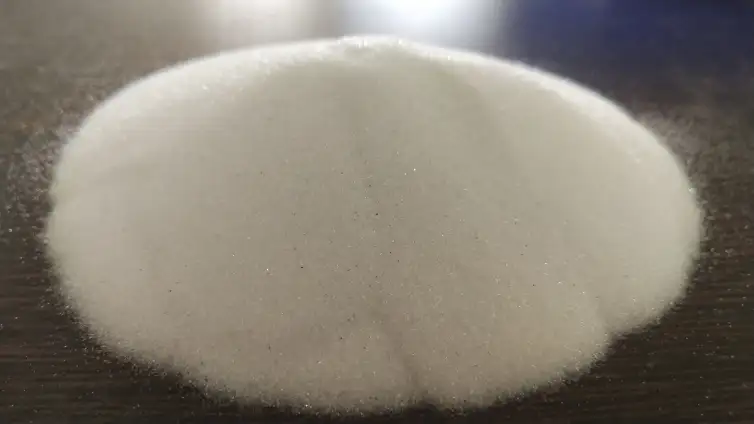

Glass Bead 0.84-0.59mm blasting is a procedure in which compressed air, mechanical high-speed spinning wheels, or water pumps force small angular or spherical particles apart. The blast media type, shape, size, density, and hardness, as well as media acceleration and volume, as well as blasting distance from the workpiece, angle of impact, and time cycles, all play a role in the blast process capabilities.

The glass bead 0.84-0.59mm blasting equipment is designed to distribute, reclaim, and hold the media, as well as to contain the blasted portion and collect the blasting dust. Individual parts can be processed in a batch process or automated by the system. We provide glass beads for shot blasting, shot peening, road marking, and many other applications. We are one of the top suppliers of all types and sizes of glass beads in India and throughout Rajasthan.

The Glass Beads Price in India is determined by the quality control element as well as the workability it provides within its limits, as glass beads are fairly safe when compared to other forms of blast media. Glass beads, in particular, are a suitable alternative to silica depending on the purpose. Because of the high quality of the products, glass beads with mattle finish are also a popular choice. They also have the advantage of lasting multiple cycles before needing to be replaced. Another popular commodity is steel grit. Glass beads can also be utilized in suction or pressure blast cabinets.

We are a well-known Glass Beads Manufacturer in India. We also create glass beads at a reduced cost for sale in Rajasthan. Glass beads are a common abrasive ingredient in blast cleaning. It can produce a tasteful, smooth finish, be used for NDT Blast Preparations, or even deliver a flawless surface devoid of consumption or tainting without changing the form or impinging on the surface being dealt with, depending on the size used and when used effectively. We also manufacture high-quality copper slag.

Air Blast Delivery Systems are divided into two categories.

1.)SUCTION:

The venture principle is used in Suction Blasting Cabinet, which involves sucking media from a hopper. The air jet is 1/2 the diameter of the nozzle, and as the air stream passes through both, a low pressure is created, sucking the media from the hopper into the air stream. The media acceleration distance is quite small (about 4 to 14" from the nozzle to the workpiece).

As long as there is blasting media in the Sand Blasting Hopper, the suction systems work perfectly and can keep blasting continually. Suction systems struggle to deliver media at low air pressures (5 to 25 psi), and the length of the suction feed hose is limited. Suction blasting cannot carry very heavy blasting (bigger steel media) into the air stream. The majority of industrial blast cabinets are suction systems that can handle a wide range of material.

2.) PRESSURE:

Glass Bead 0.84-0.59mm blasting using pressure pots, which are ASME-approved pressure containers of various diameters. The media is contained in the pressure pot, which is pressurized thanks to compressed air. When the air/media combination is released from the pot, it travels at least 5-10 feet via the hose before speeding up as it passes through the ventura of the Sand Blasting Nozzle.

In pressure blasting, the air/media combination accelerates at a significantly faster rate than in suction blasting. When the media and air in the pressure pot have been used up, the pressure pot must be depressurized before it can be refilled with media. When compared to suction systems, Pressure Blasting Cabinet systems are far more productive. Pressure systems can blast any type of media, regardless of weight or size, and they can also deliver media at very low pressures.

| Visual | Mechanical |

| Bright Matte Finish | Deburring |

| Dull Matte Finish | Deflashing |

| Satin Finish | Paint and Coating Removal |

| Satin Luster Finish | Peening |

| Blending of Tool Marks | Pre Paint and Coating Adhesion |

| Removal of Weld Discoloration | Heat Treat, Mill Scale Removal |

| Surface Cleaning | Weld Splatter Removal |

| Glass Frosting and Etching | Thermal Metal Spray Prep. |

| Pre Plate and Anodize Finishes | Rust Removal |

| Mold Cleaning |