Products

*Price Range - Rs 10-100 per/kg

4.0 Star Rating by our Precious Clients

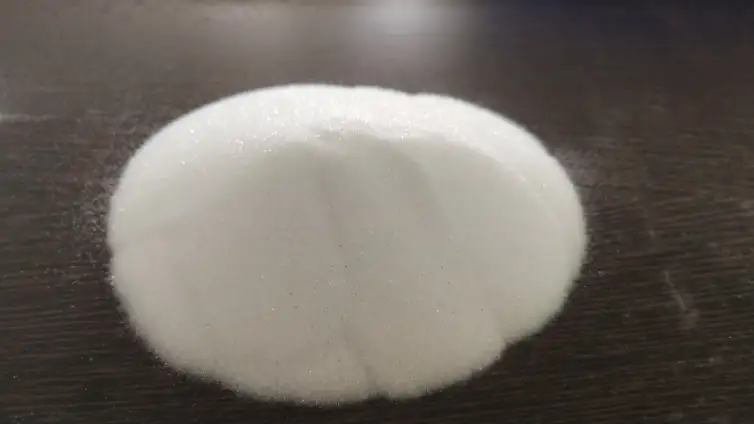

Glass beads 0.09-0.04mm are available in sizes ranging from 0 to 45 micrometers and provide a great level of satisfaction due to their cleanliness, hardness, and durability. Soda lime silicon carbide is a common material used to make these glass beads. Another alternative is a microsphere, which is made of borosilicate glass and can be customized to meet our exact specifications. Glass bead blasting is always regarded as a cost-effective method of blasting since it may be used to counteract stress cracks and corrosion. We also manufacture a wide selection of items in India at amazingly low glass beads prices.

The use of a support board while moving fragile beaded goods will help to prevent harm from flexing. Micro Glass beads can be harmed by high humidity. It encourages the formation of sweaty, crusty beads. Additionally, the threads used to connect the beads, whether cotton, linen, or sinew, will absorb water rapidly. Wet threading promotes glass disease in the holes of the beads and causes the threading material to break down. In a humid atmosphere, glass disease spreads by direct contact with other beads. Glass beads can withstand light exposure, but threading and backing materials cannot.

Glass Bead 0.09-0.04mm Price mainly depends upon the working of beads and its shining properties. There are a lot of sizes and grades of glass beads and the grade quality depends upon how many times a glass bead can be used, generally it is 4-5 of a good quality one. We are the best manufacturer and supplier of glass beads and bead blasting machines in all over India, we manufacture all grades and sizes of glass beads and blasting machines like portable shot blasting, sand blasting, cabinet shot blasting, Sand Blasting Cabinet for sale in Jodhpur, Jaipur, Pune, Delhi, Faridabad, Gurgaon, Kolhapur and all over India.

Handling Small Glass Beads roughly might cause them to fracture and break. When moving items with beads attached, take care to avoid striking or scraping the beads. The threading material used to string or attach the beads to an item must be exceptionally strong and stable. The threading material used, whether cotton, linen, sinew, or fishing line, serves as the linking element regardless of how the beads are joined. The glass beads are either lost or the band of beads loses structural stability if the threading material breaks. With modest flexing, stiff and brittle threading materials will fracture.

At the molecular level, all light promotes a photochemical reaction that breaks down threading and backing 4 materials. This photochemical process cannot be stopped once it has begun.

Glass Beads manufacturers products are frequently heavy, requiring additional support to avoid ripping or tearing of the delicate textiles, skins, or hides to which the beads are connected. When transporting needle-woven beaded products, support is extremely crucial because a single break in the connecting material might result in the loss of numerous beads.

Crushed glass grit from window glass or tempered glass should be avoided as a blasting media since it is ineffective. Crushed glass grit degrades quickly and is difficult to repurpose.

• Low-cost and high-efficiency

• Produces an etched finish with abrasive

• Made from reclaimed materials

Wear gloves to avoid getting body oils on the glass beads price surface. Sweaty glass bead 0.09-0.04mm are encouraged by your hands' oils, which also provide a tacky surface for dust and grime to adhere to. Use a support board or a sling made of cleaned muslin fabric to transport beaded goods.

Because crushed glass grit has an uneven shape, it will scratch the surface more. Crushed glass grit is commonly used for stripping and preparing a surface for coating because of this. These environmentally friendly abrasive shots are made entirely of recycled glass, including beer and wine bottles.