Application

Glass beads shot peening is a cold functioning process that is utilized to enhance the fatigue endurance and counter stress splitting of most metal purposes. In glass beads shot peening the exterior surface of the terminated part is exploded with round steel shot. Every section of the shot accomplishes like a peening flatter and when the exterior surface has been prepared all over, this inhibits the formation of tension splinterings that can commence to exhaustion and incompetence.

The appearance of a part that has been worked on by glass beads shot peening has what is termed a compressed layer that continues crack. Because most exhaustion frustration and stress incompetence originate at the exterior surface of a part, the compressed extension panel that is accumulated by glass beads shot peening accessions the survival of elements.

Following are the parts that can be availed from Glass Bead for Shot Peening :

Glass Bead for Shot Peening should be perceived that when any exterior surface capacity is accomplished on any engine component the difficult skin of the segment is destroyed and Glass Beads shot peening is suggested that some form of exterior surface treatment be transported out to restore the segment surface to its unique situation.

Shot peening glass beads has major benefits for the managed exterior surface as it increases the exhaustion characteristics of metal components and endurance to stress corrosion splitting. Shot peening glass beads, copper slag, aluminum oxide, steel grit, and many others are abrasive with common hardness (approximately 6 on the Mohs scale) and comparably low weight, therefore producing a significant extension of compression remaining stress at the exterior surface while leaving a uniform metal termination.

In the automotive industry, shot peening glass beads are utilized for eliminating rust and paint on the car bodies. Having such a precarious action, they are also utilized to clean and sanitize expensive corrective devices in the pharmaceutical manufacturer. In the aviation industry, shot peening glass beads are employed to clean and shot peening particular parts, such as propellers and aircraft engine leaves.

Another area in which shot peening glass beads are fortunately managed is road marking. The paint employed in road marking implants glass beads with retro-reflective features of the vehicle's headlight beam, assuring better clarity of the road marks throughout night and day and more comprehensive safety for car operators. Shot peening glass beads can be associated with paint prior to road marking, but can be supplemented later over the recently fresh overlay.

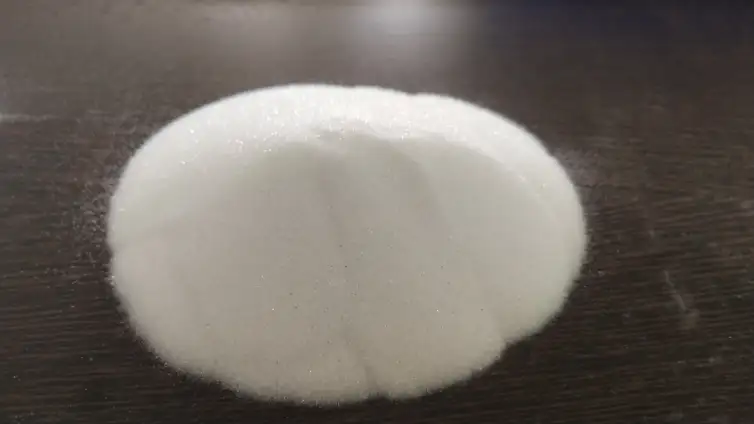

Glass beads for shot blasting implement one of the most considerate suggestions on the blasted exterior surfaces. Unlike other abrasive materials(such as aluminum oxide, plastic abrasive media, abrasive garnet sand, and many others), glass beads for shot blasting machine are an inexpensive solution for cleansing and shot peening of exterior surfaces, and are fabricated in rounded shape from lead-free recycled glass. Glass beads for shot blasting is an environmental substance that does not cause human strength problems because glass beads shot blasting does not include free silica, glass beads shot blasting is chemically inert and can be reused up to 30 terms, depending on the methods and the exterior surfaces being explored.

Glass beads shot blasting are available in different sizes. The large glass beads for shot blasting particles produce a more difficult textured termination, while the small glass beads for shot blasting particles generate an extremely bright and smooth exterior surface. Further, the scraps of the Glass beads for shot blasting and sand blasting machine can be performed in much more diminutive sizes than other metal shots, therefore, being ideal for cleaning and peening metal parts with elaborate geometries and fine angles, without calumniating their shape or eliminating sections of the base element. Being a non-ferrous and stable element, glass beads do not contaminate the blasted exterior surfaces, being successfully utilized for stainless steel, aluminum, stone, concrete, wood, glass fiberglass, plastic.

We are the leading glass beads shot blasting manufacturer in India at a low price for sale. We also supply other abrasive media such as copper slag, white aluminum oxide, large glass beads, small glass beads, micro glass beads, plastic abrasive media, cut wire shot, and many others. These abrasive media is used for surface cleaning through sand blasting machine, grit blasting machine, shot blasting machine, abrasive blasting machine, and many others in India.

We also supply thermal spray gun, arc spray gun, y spray gun, metalizing wire, blast rooms, acoustic chamber dust collector, and many others at an economical price in Rajasthan which is used for coating after surface cleaning.